Our Responsibility

" Early on in our more than forty-year company history, it was important to us to carefully weigh up ecological and economic concerns and to bring them into a sensible relationship. For us, sustainability is more than just a buzzword – we live it and see ourselves as responsible for people and nature, now and in the future. At Hepco & Becker, we stand by our honest promise at all times, worldwide, to bring only long-lasting quality items to the market."

Paul Erhardt Senior

ENVIRONMENTAL PROTECTION AND SUSTAINABILITY

This begins with the development and manufacture of our products. This includes short distances, the reduction of material and energy consumption as well as nature-friendly material cycles and waste avoidance. For example, we conserve valuable resources by using solar power we generate ourselves, use a sophisticated recycling concept to recycle production leftovers and strive not only to comply with environmental standards in production, but also to exceed them.

We also ensure the sustainability and longevity of our products through our qualified, fast and often praised repair service. But if damage does occur or you have another problem with your item, then our service keeps what it promises: immediate and competent help.

We keep our products "alive". Defective components are largely replaced or repaired by us. Nothing is more environmentally friendly and efficient than maintaining existing parts. The production process of our leather and its control are also important factors for us. Above all, we assume species-appropriate animal husbandry and expect the leather to be tanned in full compliance with European environmental standards. Even with many small steps you can make progress.

For example, we compensate for the CO2 emissions caused by our paper consumption by participating in climate protection projects that change every year. This compensation alone would be enough to circumnavigate our globe several times on a motorcycle. Products from Hepco & Becker impress with their quality and durability with a guarantee of 5 years.

Our new solar system

Social and human responsibility

Social and human responsibility Hepco & Becker is a globally active, medium-sized company and a major manufacturer of motorcycle accessories. For 45 years now, motorcycles have been upgraded and individualized with our model-specific products. We currently employ around 80 people at our location in Pirmasens. It is very important to us that the people who manufacture our products are paid fairly. Therefore, we also demand from our producers and suppliers that they pay their employees appropriately. Respect and decency requires that people can live from their work and find socially acceptable working conditions. Our employees should not only be able to do their work safely, but also stay healthy. We stand by our special responsibility towards our employees, which does not end at the factory gate. It is also important for us that we get involved locally and with local clubs and support the children and youth work there financially.

Children are our future! And yet they often have no lobby and sometimes come up short in many areas of life. Even here in a wealthy country like Germany. The German Child Protection Association (DKSB) has made it its mission to change this. With its committed work, the DKSB is committed to a child-friendly society in which the mental, psychological, social and physical development of children and young people is promoted. It is not only about political work, but also about very practical help and support on site. Here in Pirmasens, the local branch of the child protection association has been active since 1978, supporting families with problems of all kinds and has thus already provided support to a large number of children in need of protection and help. Whether it's clothes, help or food, a healthy lunch or help with homework, leisure time or joint excursions - the members of the Pirmasens local group are always there for the youngest in our society, helping voluntarily and selflessly.

We at Hepco & Becker admire this commitment, are happy to help and have supported the work of the local association for many years with a regular, annual donation. "We are very happy about it!" emphasizes Wolfgang Baumgart from the Pirmasens Child Protection Association. “The money flows into our active daily work. Among other things, we are currently taking care of around 20 primary school children, offering them wholesome food and helping with clothing and homework.” For us at Hepco & Becker, this support is also an investment in the future. It is well known that children are our future and we are very happy to be able to make a small contribution to ensuring that these children can also look forward to a positive future.

PRODUCTION

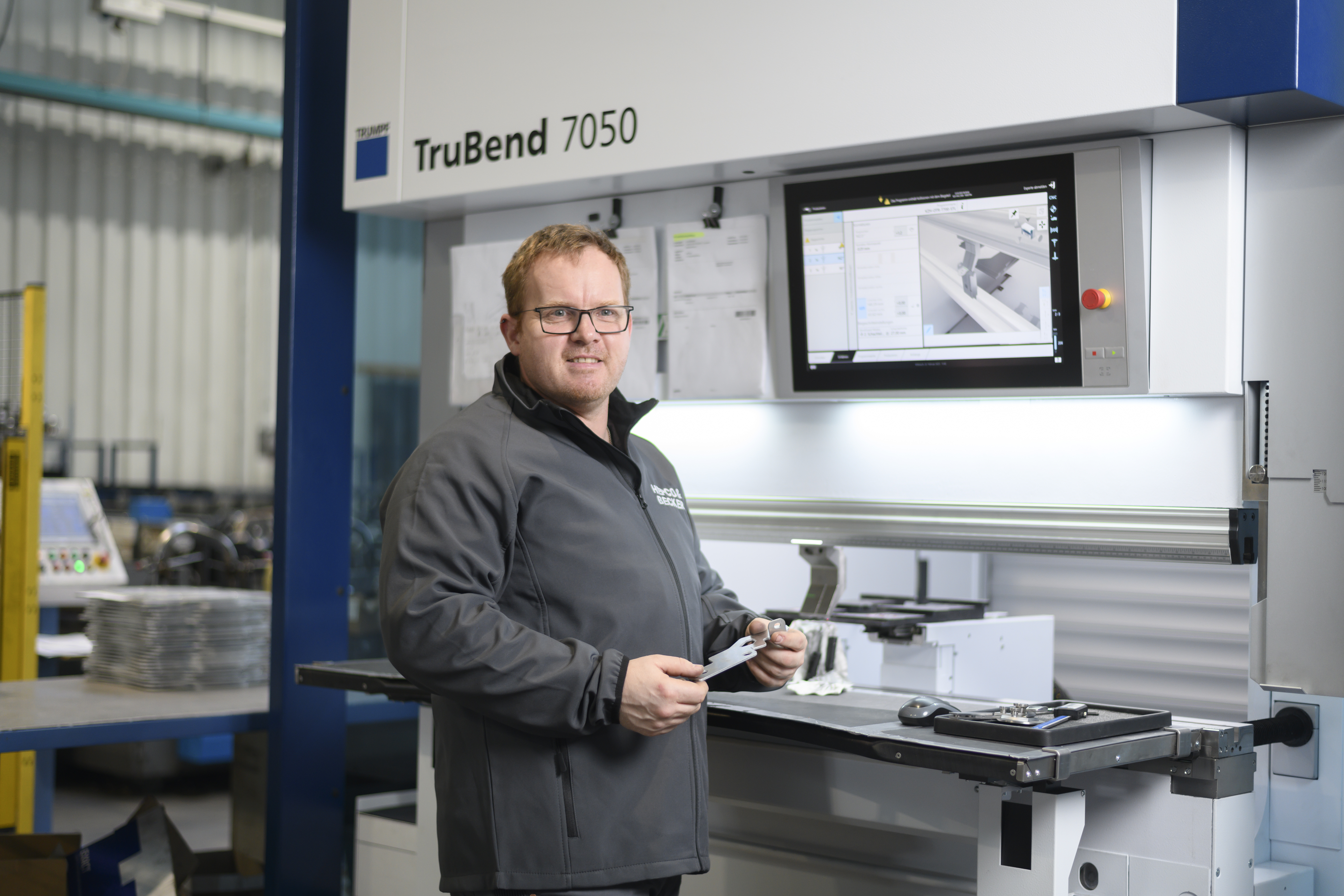

Only the combination of trained skilled workers and highly efficient machines bring a product on the way, which is worthy of customer requirements and areas of application all over the world. Completely Made-in-Germany, thanks also to German suppliers of the raw materials, consumer goods are produced with high demands on design.

The ability to deliver exclusive small series is more important to us than ever. Keeping motorcycles and accessories alive and appreciating them over the years also carries the idea of a sustainable corporate philosophy. That's why we still offer luggage racks for old and youngtimers with our Hepco & Becker Classic products, even after more than 45 years. This requires know-how and a great deal of knowledge from our employees, who, with great technical expertise, implement this small series production at today's increased level of quality. The experience of each employee is reflected in the end product. The raw materials are processed in a conventional way, as workshop production or in a highly mechanical, industrial way. In this way, customer-related special orders can also be realized with great attention to detail. In a part of the new premises, production is now carried out on the most modern machines in the industry. Tube blanks are first pre-cut by a semi-automated tube laser according to the contour before they fall every second onto the conveyor belt for further processing. The tubes are then shaped burr-free and dimensionally accurate on the tube bending machine before they are welded on the new KUKA welding robot with 2-cabin equipment.

The high accuracy of fit of the add-on parts is very important and is ensured by the new, advanced production. This dimensional accuracy is also possible in larger production series through the use of additional test gauges in the subsequent quality control, which precedes the surface refinement.